latest news

Why fall protection inspections are crucial

By Mark Dolan, General Manager Roof Edge Fabrications

If you are responsible for a building you are legally required to make sure that work equipment is safe to use. This is vital if you have fall protection equipment on your roof as a faulty system could quite easily result in serious injury or even death.

Over the coming weeks I’m going to discuss the importance of annual inspection and certification and explain what’s required when it comes to recertification of both personal and collective fall protection systems.

Legal Obligation

Once work at height equipment has been installed, you have a legal duty to ensure that it is properly maintained and examined at least once a year as outlined in standards such as BS EN 365 and BS EN 7883 and legislation including Workplace (Health, Safety and Welfare) Regulations and the Personal Protective Equipment at Work Regulations.

For example, BS EN 365 Personal Protective equipment against falls from a height. General requirements for instructions for use, maintenance, periodic examination, repair, marking and packaging outlines general requirements for periodic inspection and states the components should be examined ‘at least’ twelve-monthly.

If you fail to comply with these standards and legislation, and an accident occurs, you can be held responsible if the equipment is found to be faulty and/or uncertified.

Insist on Competency

When arranging for equipment to be recertified, it is vital that the person doing the work has adequate knowledge of the equipment and is competent to assess the risks. Always make sure the person or company you are employing are competent and that you have all of the relevant historic documentation for the equipment.

A person should be able to demonstrate their competency through certification and experience while a company should be a member of a recognised industry group or association and have the relevant health and safety accreditation such as SAFEContractor.

EN 365 sets out clear guidance on the required capabilities of a person carrying out periodic examination of systems:

This person should be capable of identifying and assessing the significance of defects, should initiate the corrective action to be taken and should have the necessary skills and resources to do so.

A competent person may need to be trained by the manufacturer or his authorised representative on specific PPE or other equipment, e.g. due to its complexity or innovation, or where safety critical knowledge is needed in the dismantling, reassembly, or assessment of the PPE or other equipment, and may need to have that training updated due to modifications and upgrades.

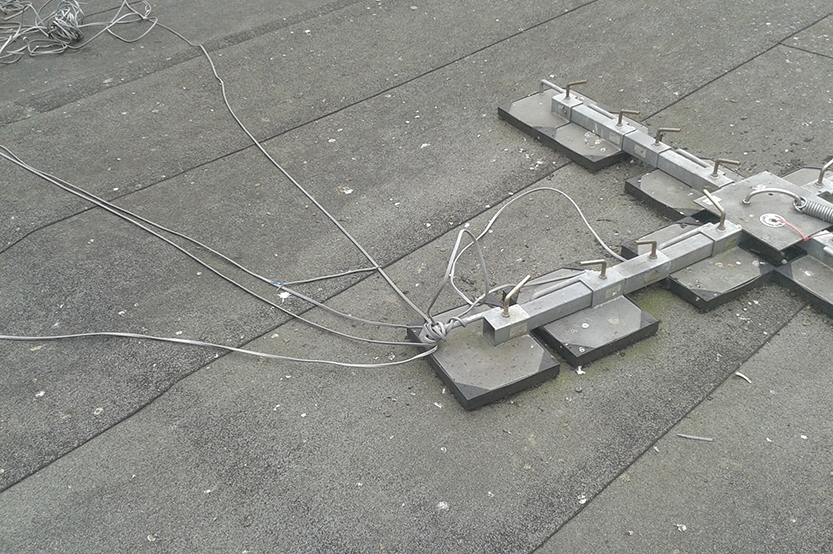

What can go wrong with a system?

Next week I’m going to look at why it’s important to have your personal fall protection systems such as lifelines inspected annually and then conclude this series with a look at recertification of collective systems including guardrails.