latest news

The importance of personal fall protection recertification

According to the Health and Safety Executive companies in the UK are legally required to provide a ‘safe working environment’.

This means that once a fall protection system, whether it is a ‘collective’ system such as guardrail or a ‘personal’ system such as eyebolts, is installed, it must be regularly inspected, maintained and serviced to ensure it is safe to use at all times.

If a system is found to be faulty or uncertified after an accident then whoever is responsible for ensuring that system is recertified could be held accountable. The HSE has extensive powers to punish those who have not met their responsibilities.

Though it is important to ensure all types of fall protection systems are properly inspected and recertified, nowhere is the danger of lax inspection standards more apparent than with personal fall protection systems.

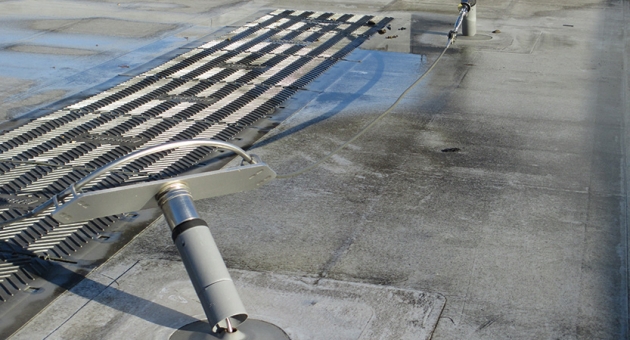

Personal fall protections such as lifelines and eyebolts typically consist of an anchor point, a lanyard - fixed length if the system is fall restraint - and a full body harness. When compared with collective systems such as guardrails, there are more points of failure and due to the systems being user dependent, the immediate risk is greater.

It’s not uncommon for fall protection systems such as these to be removed, damaged or tampered with, or in some cases for the system to be deployed. As a result they must be inspected regularly and recertified in order to ensure that they are safe to use.

The frequency of inspections and recertification will depend upon the system, frequency of use and environment, but as a rule visual inspections should be carried out before each use and official re-certification should be carried out at least every twelve months.

.jpg)

Inspection and rectification of equipment must only be carried out by a competent person and should include a full inspection of the system and associated PPE, for example:

- a detailed inspection of the structural connection of the system

- making sure the system runs smoothly over all intermediate brackets

- annual pull testing of swage terminations in accordance with the manufacturers recommendations.

- inspection of all shock absorbers

- checking the cable for any damage, kinks or signs of wear

- checking and tightening of all accessible fixings

- looking for any signs of corrosion to galvanised components

- pull test for all visible end fixings to concrete/brickwork/ structure

- re-tensioning of the cable if required

- inspecting lanyards and harnesses for cuts, stains, fraying or breaks in stitching

- looking for signs of damage to fittings (e.g karabiners, screwlink connectors, scaffold hooks)

- checking for damage to the sheath and core of the rope

Inspection and recertification of systems is much more than simply ticking a box and issuing a certificate which is why it’s essential that you only employ a competent company/person to carry out the recertification of your equipment and systems.

Roof Edge offers a recertification service for all types of fall protection systems.

We can inspect your equipment and provide you with correct certification or advice on how to make your systems compliant. For more information on our recertification service, click here, call 0141 949 1014 or use our online contact form.